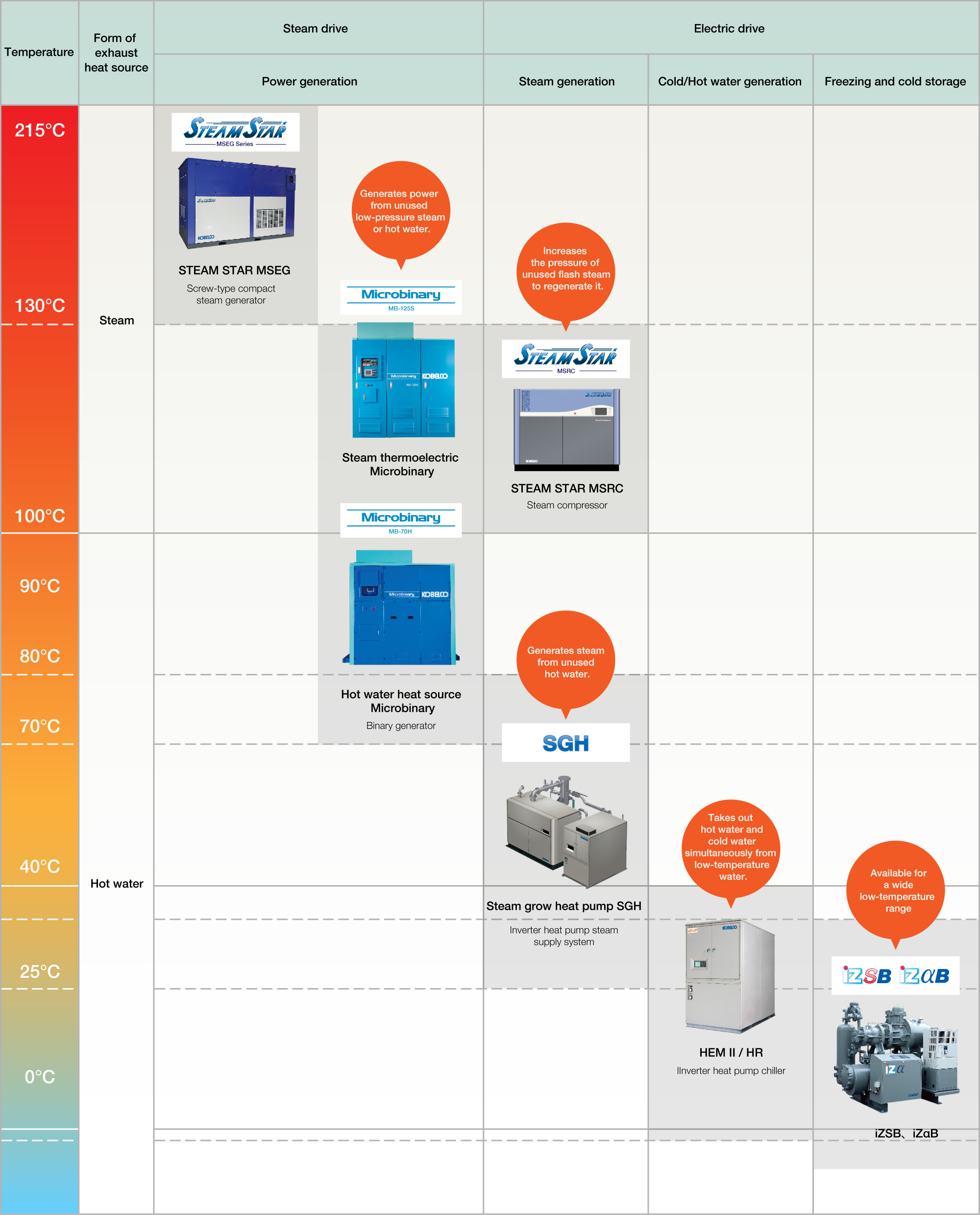

We offer a wide range of power-saving and power-generation menus utilizing screw-type compressor technologies to meet the needs for energy saving and reduction in CO2 emissions.

As power generation and power saving are attracting attention, we have a lineup of power generating equipment that uses hot water and steam. The main feature is compact generators with a screw turbine, which are our unique power generation equipment that other companies do not have, and these generators use energies that were not used before, such as heat, to make small-scale decentralized power generation available at factories and hot springs. We have a lineup of products that can handle every temperature range.

| Product name | Model | Energy recovery form | Power generation amount/Recovered heat output (Per unit) | Application example |

|---|---|---|---|---|

| STEAM STAR MSEG | Screw-type compact steam generator | Power generation | Up to 160kW | ■ Substitution for reducing valves ■ Use of excess steam |

| Microbinary MB | Screw-type compact microbinary generator | Power generation | Hot water: Up to 65kW Steam: Up to 112kW |

■ Cooling and hot water for each process ■ Steam and exhaust gas ■ Hot waste liquid |

| Applicable form of exhaust heat | ||||||

|---|---|---|---|---|---|---|

| Steam | Gas other than steam | Hot water | Cold water | Brine | Waste liquid | |

| STEAM STAR MSEG | ● | |||||

| Microbinary MB | ● | ● | ● | ● | ||

Flash steam and low-pressure steam after being used in factory processes have been difficult to recycle despite their significant amount of thermal energy. MSRC can regenerate steam by efficiently increasing the pressure of this flash steam with a screw-type compressor and returning it to the process side.

| Product name | Model | Energy recovery form | Power generation amount/Recovered heat output (Per unit) | Application example |

|---|---|---|---|---|

| STEAM STAR MSRC | Screw-type compact steam compressor | Steam regeneration | Up to 1,450kg/h | All steam users |

| Applicable form of exhaust heat | ||||||

|---|---|---|---|---|---|---|

| Steam | Gas other than steam | Hot water | Cold water | Brine | Waste liquid | |

| STEAM STAR MSRC | ● | |||||

Because heat pumps used for air conditioning of buildings and factories can utilize many times the amount of thermal energy as supplied energy (electric power), they are becoming increasingly popular as energy-saving equipment. Water-cooling type heat pumps, in particular, have achieved overwhelming high efficiency.

| Product name | Model | Energy recovery form | Power generation amount/Recovered heat output (Per unit) | Application example |

|---|---|---|---|---|

| SGH | Steam supply heat pump system | Steam generation | [SGH120] 341 to 567kg/h [SGH165] 483 to 866kg/h |

Processes that need a steam heat source, such as drying, sterilization, distillation, and concentration |

| HEMⅡ | Water-cooling inverter screw chiller | Heating, cooling, and ice making | [Only for cold water] Cold water:351 to 580kW [Cold and hot water] Cold water:276 to 456kW Hot water:351 to 566kW |

■Air conditioning and cooling in buildings and factories ■Renewal from the suction type |

| HEM-HR75S/ HEMⅡ-HR | 75°C compact high-temperature heat pump chiller/70°C high-temperature heat pump chiller | Heating and cooling | [Cold and hot water] Cold water:90 to 590kW Hot water:134 to 680kW |

Buildings and factories that need air conditioning/cooling and hot water supply simultaneously |

| HEM-HR-TB | Ice making heat recovery chiller |

Heating, cooling, and ice making | [Ice making and hot water] Brine:129 to 220kW Hot water:197 to 326kW |

to Factories that need brine cooling and hot water for washing, etc. simultaneously |

| HEM-HR90 | 90°C high-temperature heat pump chiller | Heating and cooling | [Cold and hot water] Cold water:146 to 321kW Hot water:230 to 415kW |

Factories that need hot water for washing, drying, sterilization, defrosting, etc., and cold water simultaneously |

| HEM-3WAY | Heat balance/heat pump | Heating and cooling | [Cold and hot water] Cold water:90 to 180kW Hot water:128 to 261kW |

Factories that need hot water for washing, drying, sterilization, defrosting, etc., and cold water simultaneously |

| Applicable form of exhaust heat | ||||||

|---|---|---|---|---|---|---|

| Steam | Gas other than steam | Hot water | Cold water | Brine | Waste liquid | |

| SGH | ● | ● | ||||

| HEMⅡ | ● | ● | ● | ● | ||

| HEM-HR75S/ HEMⅡ-HR |

● | ● | ● | |||

| HEM-HR-TB | ● | |||||

| HEM-HR90 | ● | ● | ● | |||

| HEM-3WAY | ● | ● | ● | |||

As a pioneer of screw refrigeration compressors, we have taken the lead in the industry all along, always responding to customer's needs with innovative ideas and proposals.

In 2002, we released the “iZ series,” capacity-increased energy-saving two-stage compressors, which are the world’s first screw refrigeration compressors equipped with an inverter.

The following year, we released the “iZα series” which has employed a new refrigerant R404A having zero ozone depletion potential.

Achieving increased capacity and outstanding energy-saving performance at the same time, the iZα series is being highly acclaimed by customers as an unheard-of epoch-making refrigeration compressor.

| Product name | Model | Energy recovery form | Power generation amount/Recovered heat output (Per unit) | Application example |

|---|---|---|---|---|

| iZSB/iZαB | Energy-saving inverter-controlled brine chiller/brine chiller for low temperature | Cooling | 49.3〜365.4kW | Cooling of factory processes for chemicals, foods, etc. |

| Applicable form of exhaust heat | ||||||

|---|---|---|---|---|---|---|

| Steam | Gas other than steam | Hot water | Cold water | Brine | Waste liquid | |

| iZSB/iZαB | ● | |||||