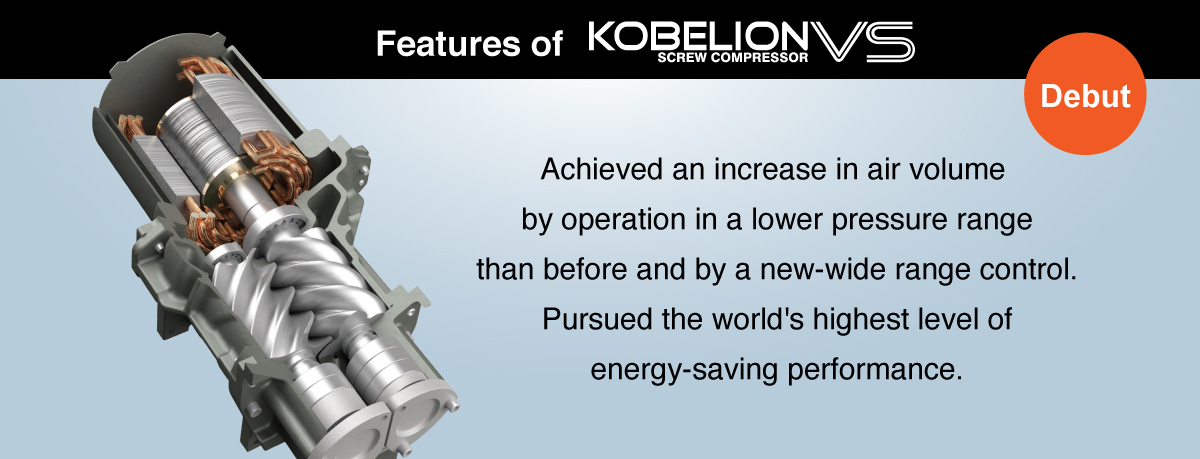

The new-generation KOBELION is equipped with sophisticated high functions, including a next-generation screw, a newly-developed intake valve, a super premium efficiency IPM motor, a dedicated inverter, a new color touch panel, and a remote monitoring system (Kobelink).

The best high-performance screw compressor that has collected advanced technologies such as a motor directly connected to an IPM (equivalent to IE4).

Advanced technologies such as a direct gear drive structure and unswerving reliability are highly integrated.

The direct-coupled overhang structure which is the DNA of the KOBELION VS series has become more advanced.

■ High efficiency

A screw rotor and a motor shaft have been integrated to have a completely direct-coupled structure. Power transmission mechanisms such as a belt, gear, and coupling have been eliminated to minimize mechanical loss to the utmost.

■ Easy maintenance

・Belt adjustment and replacement are unnecessary. Replacement of the motor bearing and grease application are also unnecessary.

・The overhang structure has eliminated the need for a bearing on the anti-load side of the motor. Because of the sealing structure, no mechanical seal is used and the number of maintenance parts has been reduced.

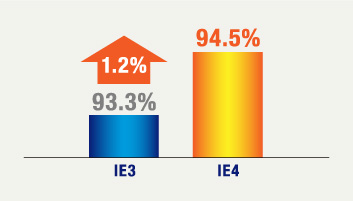

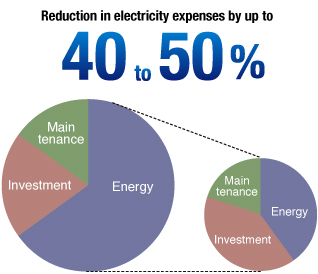

The new-generation KOBELION VS series is equipped with a super premium efficiency IPM (Interior Permanent Magnet) motor which is equivalent to the international standard IE4 class (*). It has achieved energy saving in all ranges. The employment of an oil-cooling jacket structure has further increased environmental performance for operation at high temperatures. This model also adopted an insulation class of H (allowable maximum temperature: 180°C) which is higher than the industry standard.

(*) The efficiency level of a motor is specified by the global standard, IEC (International Electrotechnical Commission) standard, and the efficiency classes are classified into IE1 (Standard Efficiency), IE2 (High Efficiency), IE3 (Premium Efficiency), and IE4 (Super Premium Efficiency). Since the IPM motor is a synchronous motor, it is not covered by the above standard. However, the IPM motor provided in the VS series boasts its efficiency better than IE4 of induction motors, and it can also maintain high efficiency in a wide load range.

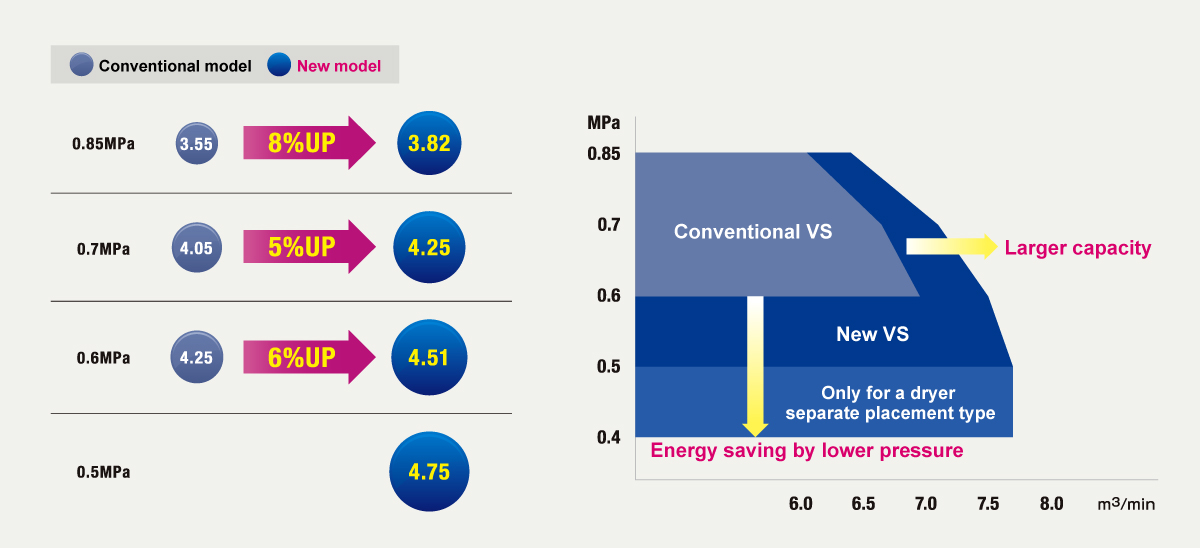

If it is used at 0.5 MPa, a unit smaller by one size may be enough. However, pursuing the relationship between pressure and air volume will lead to further energy saving. This is the new wide-range control. KOBELION VS automatically detects line pressure and increases air volume. For more efficient energy use. We provide a higher value to you as a pioneer in the control of increase in air volume.

■ Drastic increase in the amount of discharged air

(m³/min)

| Model | 0.85MPa | 0.7MPa | 0.6MPa/ | 05MPa | 0.4MPa |

|---|---|---|---|---|---|

| VS22AⅣ | 3.82 | 4.25 | 4.51 | 4.75 | 4.75※ |

| Conventional ratio | 108% | 105% | 106% | ー | ー |

| VS37AⅣ | 6.4 | 7.1 | 7.5 | 7.7 | 7.7※ |

| Conventional ratio | 106% | 107% | 108% | ー | ー |

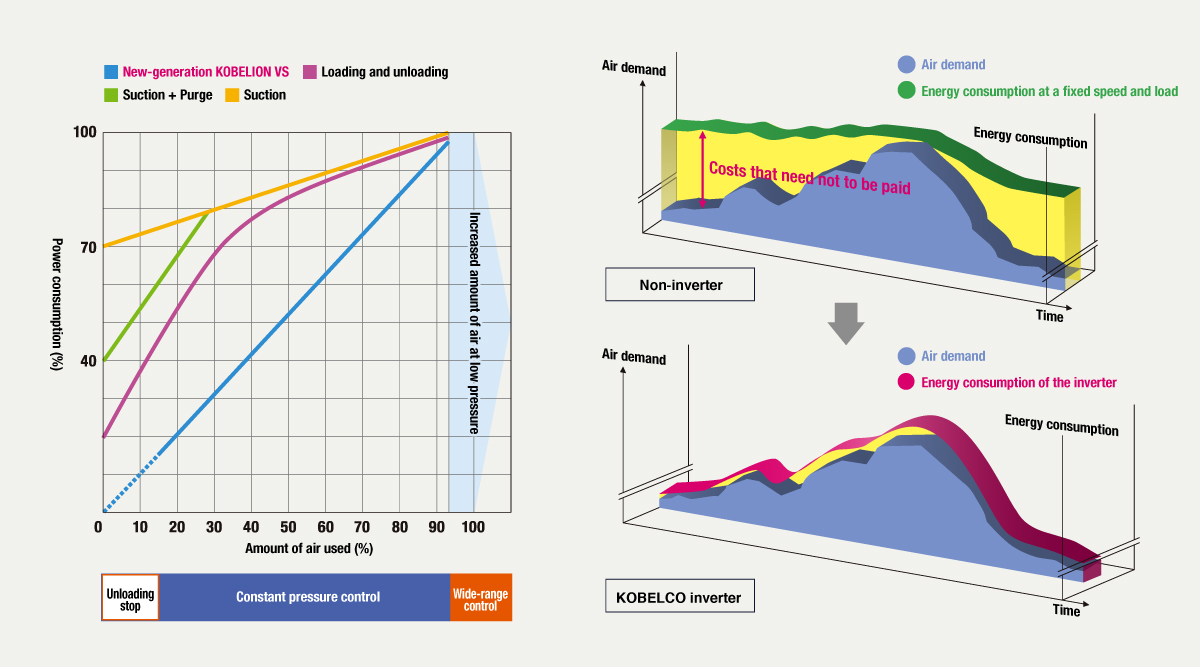

※*Only for a dryer separate placement type

Since KOBELCO adopted permanent magnet motors for its inverters in 1998, it has accumulated abundant know-how for about 20 years. The wide-range control and the direct-coupled overhang structure are just one part of it. These technologies are the results of the efforts to refine KOBELCO’s inverter control technologies that have supported energy saving in Japan and all around the world. Supplying a required amount of air and required pressure. When put into words, it sounds very simple, but it is actually very difficult to control rotation speed quickly in response to a factory load that changes from moment to moment. KOBELCO’s unique strength of establishing control algorithms on its own without relying on existing inverters is proven by the instantaneous power, speed, and smoothness of KOBELION VS. This model minimizes unnecessary pressure variation and achieves the maximum energy-saving performance.

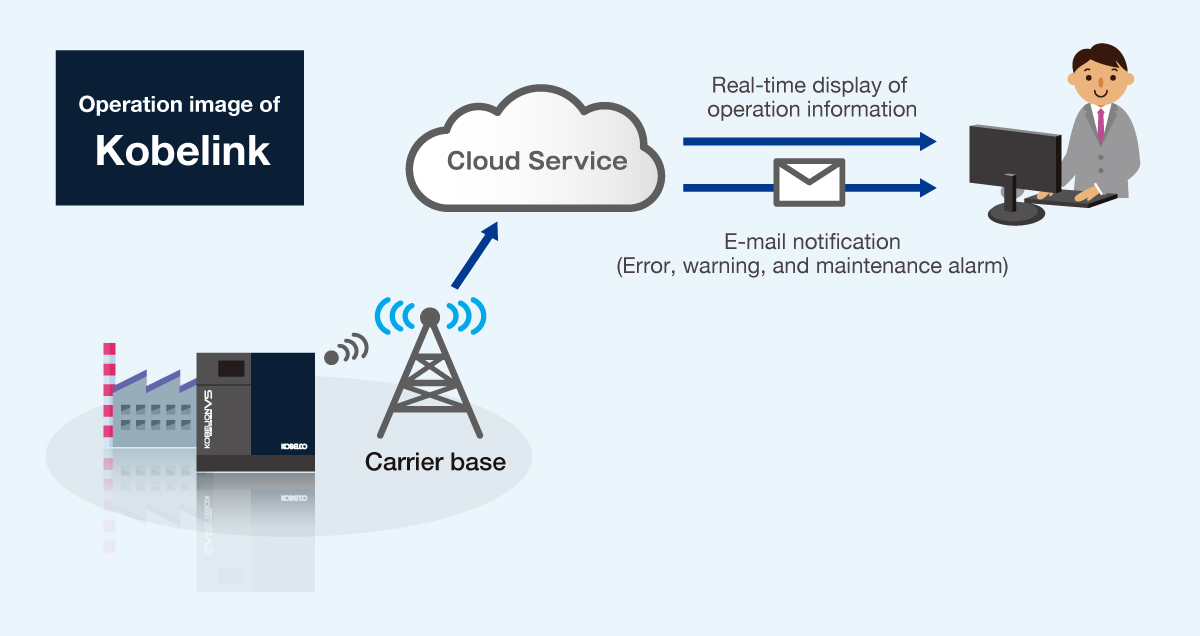

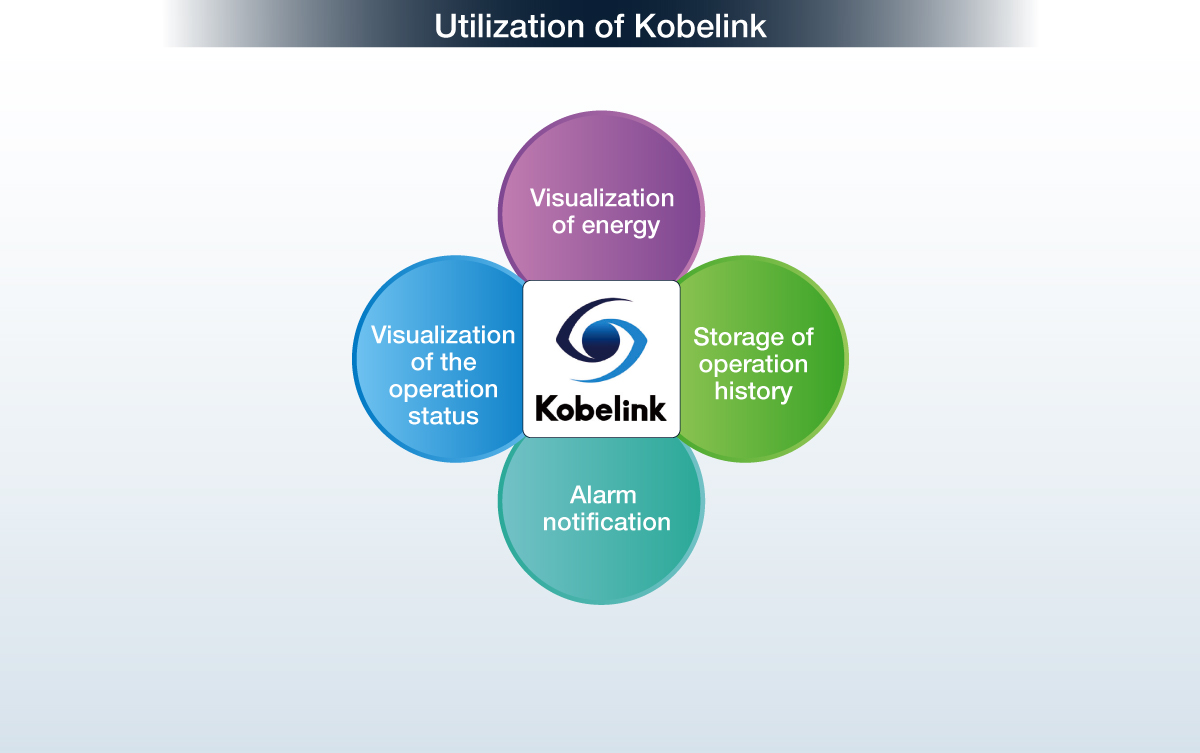

■ You can check the operation status anytime and anywhere.

This service provides real-time display of an operation status through the network, and it enables you to check the operation status of the machine anytime on the PC through automatic e-mail notification sent when an error, warning, or maintenance alarm is issued.

。

●Reliable security management The VPN (Virtual Private Network) system is adopted for communication. By encrypting data, a reliable security equivalent to a dedicated line is ensured on the internet. The risk of information leakage can be avoided.

※ “Free of charge” means that a customer does not have to bear communication costs on the compressor side and communication equipment costs. (Internet connection costs and packet communication fees for browsing data on a PC or a smartphone need to be borne by the customer.) This requires you to agree about the use of Kobelink when placing an order for KOBELION IV. If the communication equipment is shipped after the compressor has been delivered, you need to pay the communication equipment costs even for KOBELION IV.

Communication equipment costs may be charged for models other than KOBELION IV. The conditions may differ for overseas use.

Contact our sales representative for more information.

This series was designed to ensure adequate durability not to make an abnormal stop even at the ambient temperature of 45°C.

The unnecessity of belts makes it possible to save the labor of maintenance.

Small unit series

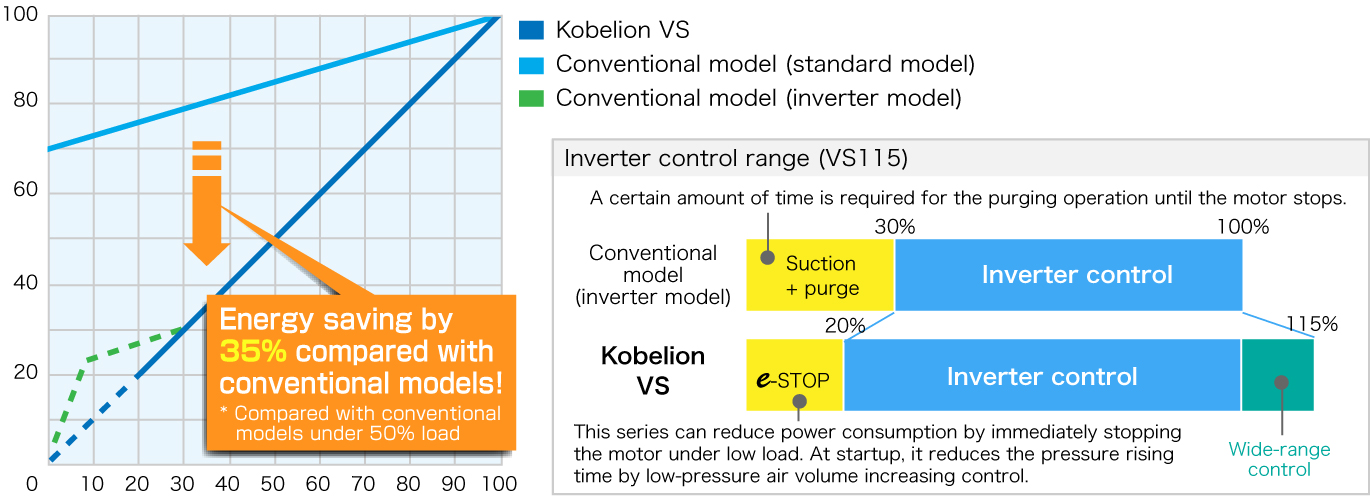

Achieved increase in air volume by the control of an inverter directly connected with IPM motor and by wide-range control

Excellent standard model with increased durability, convenience, and ease of maintenance

By expanding the inverter control range between 20 and 115%, this series achieves the best energy-saving operation even with any load change.

15kW〜400kW